Asset management software.

SmartSub is an asset condition-based asset management system developed by the US multinational Qualitrol. In Brazil, Spin is the exclusive distributor of the product. The system is a real-time platform, through which it is possible to monitor the health of an asset based on its maintenance history, unique characteristics, current performance and information on the environment in which it is located. These deliveries allow the maintenance team to prioritize field actions, carrying out well-targeted preventive and predictive maintenance, as well as allowing the identification of critical problems, avoiding irreparable losses.

Asset management is a topic closely aligned with the digital transformation. Therefore, when we talk about SmartSub, we are also talking about connection with several other systems of a utility. The more information available to SmartSub, the more powerful it is.

Digital Transformation Challenge for Energy Utilities

A system that integrates different subsystems into a single solution.

Security of data collection, storage and control.

Security rules in order to control the flow of information.

Database for storing collected information and information that will be fed by users.

Access to stored data is restricted and fully controlled.

Automatic oscillography collection, substation equipment data collection and storage, IED inventory, parameterization file management, adjustment order management, substation document management, real-time status control, communication status control substations, IED failure control, IED settings verification, IED configuration change control, equipment status control.

Intelligent data handling.

System that guarantees the automation of the analysis of stored data and enables the automatic generation of occurrence reports.

Real-time comparisons and check the status of substation equipment, based on the history and established database.

Intelligence to analyze and process data.

Communication interface with other systems, such as SAP and SCADA.

Network fault locator capable of performing some automations, real-time comparisons and generating reports and trends in equipment operation.

Integration with fault locators, event pre-analysis, maintenance data analysis, data reading, condition setting or machine learning for substation equipment (transformers, circuit breakers, batteries, etc.), reports and automated maintenance orders , failure prediction (diagnosis and prognosis), current balance in substations.

Possibilities of Integration

From the origin

From legacy systems

Data presentation

Analytics and machine learning

Available features

Artificial intelligence

Machine learning

Specialized analytics

Cloud hosting

Active and passive communication with IEDs

Market protocols

Risk analysis

Sending e-mail, SMS, Telegram

Reports

Asset history

Images

Example of how to see transmission lines

- Display of oscillographies existing in the database for interpretation by the engineering staff, issuing reports.

- Display of fault location data provided by specific IED, phase fault or interruption alarms, active alarms and dispatch of field teams for service.

Software modules

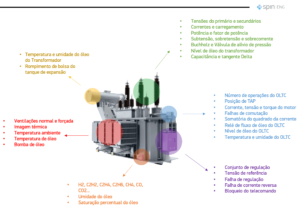

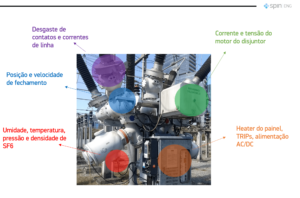

Monitoring

Display of real-time measurements of data of greater technical value for engineering and maintenance, helping decision making and process performance, in a different approach to the operation.

Display of correlation between the measured data and the IED that collected the measurement, favoring the direction of maintenance teams in the field.

The display of transformer board data digitally allows easy identification of asset type, year of manufacture and main characteristics, without the need to keep comparing data with SAP.

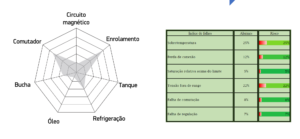

Engineering

Display of Duval’s triangles and pentagons, in addition to Rogers’ criterion, correlating data imputed by the laboratory, allows the diagnosis of partial and thermal discharge failures without wasting time calculating.

Any algorithm can be implemented by the concessionaire’s own employees, as needed, at no extra cost.

APR (Advanced Pattern Recognition)

The pattern model is based on AI and machine learning. Over time, models can be trained in a greater number of conditions, making it possible to predict behavior and issue associated alarms.

Maintenance

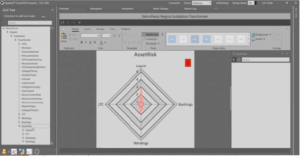

Risk management tool that enables criticality assessment of assets, allowing you to define plans and strategies for system maintenance and modernization. Forecast management in sight of the indicators monitored by the maintenance of the subtransmission. Dashboards contained in the board’s performance report.

Real-time asset health, failure probability and criticality level.